Steel foundations for elevated highway construction have seen a stellar rise in Shanghai since the first 50RF hammer was delivered to Shanghai Construction Foundation Engineering Group in 2015. As the foundation method matures, multiple research projects have been started to better understand the installation process and to define standard operation standards to guarantee optimal pile performance.

Contrary to impact driven piles that lose some of their bearing capacity after driving, vibrated piles gain bearing capacity in the months after installation as soil friction increases due to settling of the soil particles. To speed up soil settling process and the realization of bearing capacity, ICE has introduced an operation method “frequency controlled vibro driving” that allows full control of the driving process, through the monitoring of moment (VM) and rotation speed (RPM). The rationale is that the increase of amplitude at the final stage of pile installation will have a soil densification effect, the compacted soil will speed up the foundation reaching the bearing capacity specification.

In mid-July 2021 a research project designed by Tongji University was started at Chengtou Gonglu’s S3 highway construction project. The main contractor is STEC Road and Bridge and the piling work was subcontracted to Zhongtai who own an ICE 50RF vibratory hammer.

Pile parameters:

Length: 57m

Diameter: 700mm

50RF Hammer parameters

Variable Moment: 60-100

rotate speed:1500-2300 RPM

Research objectives:

(1) optimize the configuration of the vibratory hammer, by means of adding ballast weight, and by adjusting the operating frequency during pile installation.

(2) Study the impact of the hammer’s driving refusal standard on the bearing capacity. Understand how driving speed and refusal impact the bearing capacity recovery.

(3) Study the influence of pile shape on the bearing capacity of the foundation pile. Research the effect of pile parameter changes on the bearing capacity, make recommendations to optimize the pile design.

(4) Study the influence of recovery time on bearing capacity, measure the bearing capacity at set time intervals to determine the influence of different soil layers on the recovery of bearing capacity of the pile foundation.

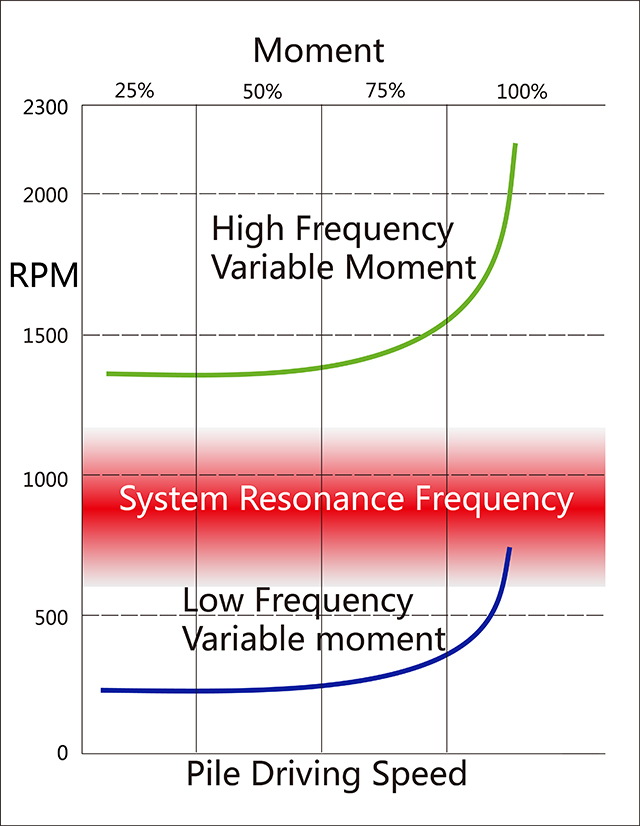

This graph shows:

A high frequency resonance free vibratory hammer

A low frequency variable moment vibratory hammer

The soil resonance frequency (also known as system resonance frequency) is dependent on soil conditions, but generally in the range of 10-20 Hz (600-1200 RPM). Resonance should be avoided in urban areas to circumvent vibration damage. The strength of the hydraulic resonance free vibro is that the operator can manipulate both the variable moment as well as the frequency of the vibratory hammer.

The pirnciple of “frequency controlled vibro driving” has been discussed in two previous postings. Follow the link "selected further reading" at the top of this webpage to read them now.

The experiment has now started, in due time we hope to share the results with our readers. If your team is working on this type of application, contact our service team for the hammer operation instructions that will help you to increase the end-bearing capacity of your piles faster.