We would like to share further research by Dr. Massarch that shows frequency-controlled driving can increase bearing capacity of pile foundations. This is a truly relevant topic for designers and installation companies of steel foundations for elevated highways who strive to reach full bearing capacity within the shortest possible time.

To make the article more accessible to Chinese researchers we have translated the abstract and a key passage below.

K. Rainer Massarsch, Carl Wersäll, Bengt H. Fellenius

Vibratory driving of piles and sheet piles – state of practice.

Proceedings of the Institution of Civil Engineers – Geotechnical Engineering

ABSTRACT: The installation of piles by vibratory methods is discussed and illustrated by case histories. The influence of vibration frequency – which can be controlled during vibratory driving but not during impact driving – on pile penetration, bearing capacity and emission of vibration is examined. The driving process affects the performance of vibratory-driven piles more strongly than impact-driven piles. Concepts are presented for assessing drivability. The importance of resonance of the vibrator–pile–soil system (system resonance) for drivability and pile bearing capacity is explained. Ground vibrations measured on and below the ground surface show that strong oscillating horizontal stresses are generated. These stresses can temporarily reduce the shaft resistance during driving, which can explain why vibratory driving is effective even in dense granular soils. Model tests show that, in granular soils, the bearing capacity of piles vibrated after driving at system resonance is significantly higher than that of piles installed only at high frequency. A concept is described suggesting that, during vibratory driving at high frequency, a zone is created adjacent to the pile shaft where the normal effective stress acting against the pile shaft is reduced due to arching. This arching effect can explain the reduced shaft resistance of piles installed at high frequency.

HIGHLIGHT FROM THE ARTICLE:

10. Proposed concept to explain the vibratory driving process

Based on the information presented thus far, substantiated by comprehensive investigations by different researchers, it is possible to propose a hypothesis to describe the efficiency of vibratory pile driving in granular soil.

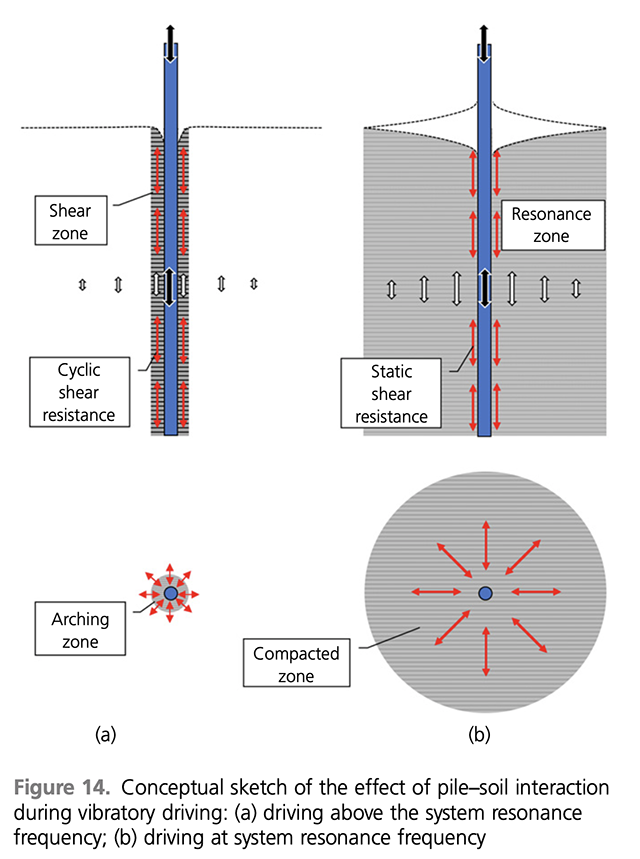

When a pile is driven at a high vibration frequency (typically >30 Hz), horizontally oscillating vibration cycles are generated that temporarily reduce the shearing resistance along the pile shaft. In addition, during pile penetration, the soil will be dis- turbed in a narrow zone surrounding the pile shaft. The effect of the interaction of the vertically oscillating pile and the soil at high frequency (>1.5 times the system resonance frequency) is illustrated in Figure 14(a). Soil disturbance (densification or loosening) will occur in a narrow zone surrounding the pile shaft. At a high vibration frequency, ground vibrations will be low and attenuate rapidly with increasing distance. According to the above proposed concept, an arching zone will be created around the vibrated pile, resulting in a reduction in the hori- zontal effective stress acting at the pile shaft. During high- frequency vibratory driving, most of the vibration energy will be emitted from the toe of the pile. When the vibrator is oper- ated at – or close to – the system resonance frequency, the pile can efficiently transmit the vibration energy to the surrounding soil. Strong ground vibrations will occur, resulting in soil densification. The compacted zone will gradually extend to a larger distance from the pile when compared with high- frequency driving. During resonance compaction, the arching zone surrounding the pile shaft is likely to collapse (Figure 14(b)). This assumption is supported by the investi- gations reported by Hartung (1994).

According to this concept, the most efficient method for vibra- tory driving of piles into granular soil is to start driving at a high frequency, thereby achieving a high penetration rate and low emission of ground vibrations. When the required pen- etration depth is reached, the vibration frequency should be lowered to approach system resonance, which causes soil densification. As a result of gradual compaction, the arching zone around the pile shaft will collapse, thereby increasing the horizontal effective stresses against the pile shaft and stiffening the pile response. It should be emphasised that the proposed mechanism is still not fully understood or proven and further investigations are needed to substantiate this concept.

The full article is available here: https://www.icevirtuallibrary.com/doi/abs/10.1680/jgeen.20.00127

ICE resonance free vibro hammers can control variable moment and frequency, we also can provide the sensor technology to measure the frequency allowing the installation team to carefully control the piling process and reach the required soil densification. If you are researching this topic, we would like to hear from you and see how we can support you in your work. Give us a call or leave your name and email address in the comments below.