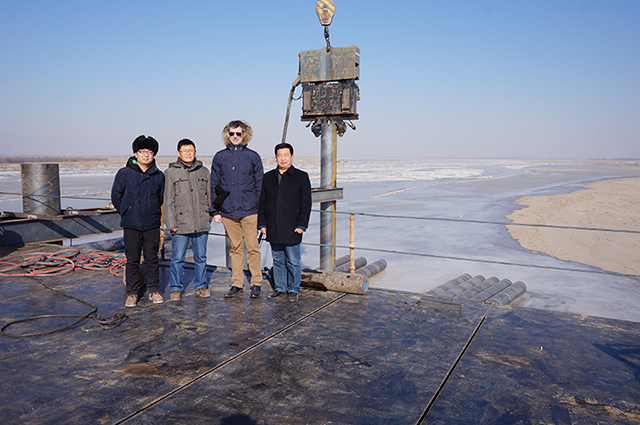

ICE is always up for a challenge and Ningxia Luqiao’s Yellow River bridge project posed a double one: sandy soils at sub-zero temperatures. On top of that it was nearly Spring Festival so logistics were more challenging than usual too. Ningxia sees large variations in day and night time temperatures at this time of year, reaching minus 15 Celsius at night and above zero temperatures in the afternoon. On the day that ICE’s Arjen van der Schoot visited the construction site at Shizuishan, to the north of Yinchuan in Ningxia Hui Autonomous Region the yellow river was running low and filled with drift ice.

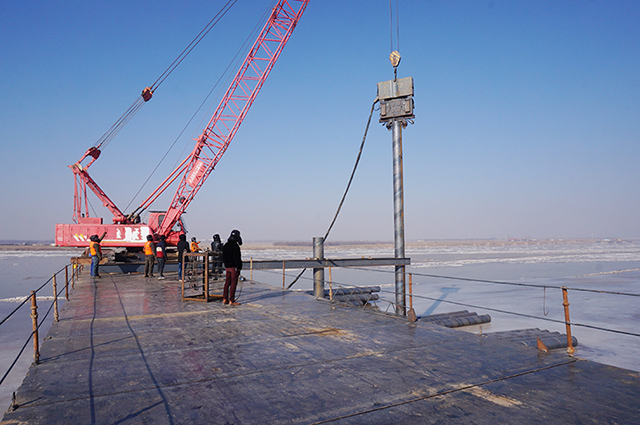

The Hongyazi Yellow River Bridge is designed to integrate the activities on the two riverbanks more closely, thereby stimulating economic development in the region. Ningxia Road and Bridge Engineering Company started construction of the trestle bridge in September 2016. The temporary bridge is finished now and platforms for the bore piling rigs are now being constructed. These platforms, that adjoin the trestle bridge, are made up of 18m long piles with a 720mm diameter. The electric 135kW hammer that was on site could only drive these piles a mere 4 meters.

At this point, the client’s chief engineer, Mr. Lin, remembered how an ICE hammer has solved his problems before: “In 2015 we had a project with sheet piles that couldn’t be driven to depth, we heard about the ICE 416L and gave it a try. What we liked about the hammer at that time was that it was lightweight and our small crane still had enough reach to lift the hammer far into the river to drive and extract the piles. Due to the higher frequency, the friction of the sand was easily overcome by the pile. When I heard of the difficulties our team had at Shizuishan I immediately recommended my colleagues to use the ICE 815C.” After a 2000km journey by truck, racing to arrive before the start of the Spring Festival Holiday, the 815C arrived on site and effortlessly drove the piles to the required 10m.

This was not a big surprise for the team at ICE. It is, however, our experience that it is very difficult to convince first time clients that making the switch from electric to diesel powered equipment will make such a difference. Of course, the difference in performance is not derived from the power source but from the fact that a hydraulic flow can achieve a much higher rotation speed of the eccentric weights (without overheating because of the forced lubrication that cools the gears continuously) than an electrically powered one can. Different types of soil liquefy at different frequencies, the ICE 815C’s frequency is nearly double that of an electric machine and effectively excites the sand particles. The main reason for the success of the hydraulic hammer is that sandy soils need a higher frequency, electric hammers compact the sand until it is like a brick and the pile driving therefor experiences refusal very quickly.

The ability of the ICE hammer in sandy soils is obvious from our rule of thumb to help select the right hammer. In sandy soils, we recommend an amplitude greater than 3 mm, in clay soils we recommend an amplitude greater than 5 mm. The soil conditions in Shizuishan were as follows: maximum water depth of 3 meters, then followed by hard sand and hard mud layers with a hardness of up to 280 kPa. The casing weighed 21t and the amplitude calculation gave a 3.6mm amplitude.

While on site Arjen answered several questions. One engineer asked after what cool down interval for the hammer we recommended. “A cool down period is actually not necessary as the hammer has forced cooling function that keeps the hammer within safe operating temperature at all times. Some precautions that I would recommend when working at lower temperatures are to upgrade the grade of hydraulic oil to a lower viscosity one so that it will perform better at low temperatures, and another is to allow for sufficient warming up time for the engine by running the power pack stationary for about 15 minutes. Also, double check the level of antifreeze in the engine water cooling system to avoid malfunctions.”

The 815C is not a one trick pony. Arjen pointed out that: ‘After the installation of the bore pile rig platforms along the trestle bridge, the 815C can be used for several other jobs on this site. After a change of beam - I would recommend the 3400mm model, that allows the clamps to clamp a maximum 2940mm diameter - the 815C could drive the 20m long 2500mm bore pile casings more efficiently than an electric hammer. After that job has been completed, we see many clients use the 815C with the 160TU sheet pile clamp to drive sheet pile cofferdams, this replaces other methods that install steel plates. The change from the 81TC clamp set to the 160TU is a matter of unbolting the beam and mounting the 160TU sheet pile clamp directly onto the hammer. “

The day after visiting the project site, Arjen called in at the clients headquarters in Yinchuan and received a thumbs up from General Manager Mr. Wang, he said “the hydraulic vibratory hammer really is good tool” !