Everyone knows that the first sheet pile of a project must be installed with great care and attention to ensure it is vertical in both planes of the wall. It is essential that the following piles are interlocked sufficiently to the preceding pile before being released and driven by the hammer. This can be achieved by preparing a trench in the wall line that increases the interlocked length prior to driving.

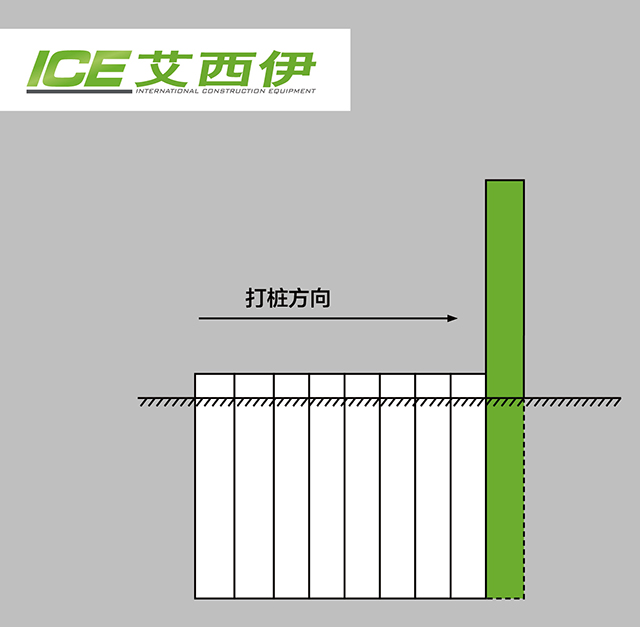

The most common sheet pile installation method is pitch and drive.Piles driven full length in one operation are more prone to deflect and go off line. This is particularly true when the soil contains debris, boulders, or other obstructions. Subsequent piles are guided by the deflected section; and within a short length of wall, pile driving comes to a halt. The sheeting must then be pulled, and the wall has to be restarted.

Drive the panel of sheets in stages - The preferred process to minimize, if not eliminate, this problem is to first set a panel of sheets and then work the panel down as a unit. This is accomplished by driving the sheets, in increments using a defined sequence. The magnitude of the increment will be determined by the soil conditions. In general, the harder the driving, the less the driving increment - perhaps 2 meters in easy driving, versus 1 meter, or less, in denser soil. Panel driving allows the piles to be guided by previously driven piles, and it lessens the possibility of driving the piles out of interlock. During this phase, as during the setting process, it's important that constant attention be paid to maintaining a plumb wall. Any deviations from being plumb that are detected should be quickly corrected before things get out of hand.

There are three popular driving methods employed when using sheet piles. Remember that each may vary according to the needs of the construction site and the composition of the soil in any given area. These are:

1.1 Pitch and drive

This method, where each sheet pile is driven to full depth before pitching the next one, is the simplest way of driving but can be practiced only for loose soils and short piles. The free leading interlock is constantly in danger of deviation. For dense sands and stiff cohesive soils or in the case of possible obstructions, panel driving is recommended.

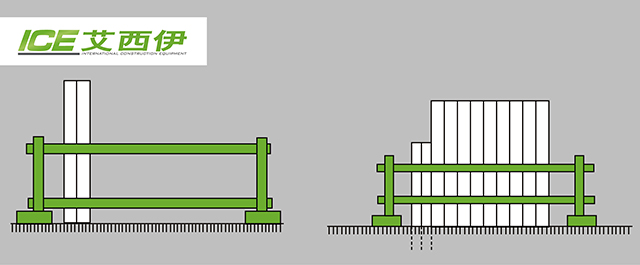

1.2 Panel driving

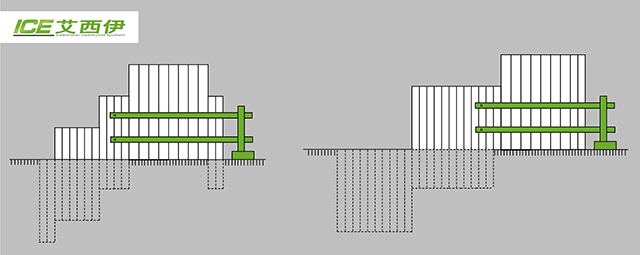

Sheet piles should be installed using the panel-driving technique to ensure that good verticality and alignment is achieved and to minimize the risk of driving difficulties or de-clutching problems.

This technique also enables greater control to be maintained on the nominal wall length. Because a whole panel of piles has been pitched there is no need to drive all piles fully to maintain piling operations; if obstructions are encountered, individual piles can be left high without fear of disruption to the overall efficiency.

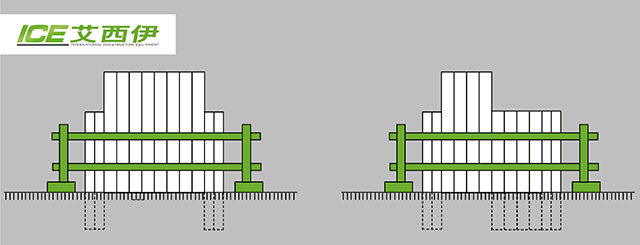

1.3 Staggered driving

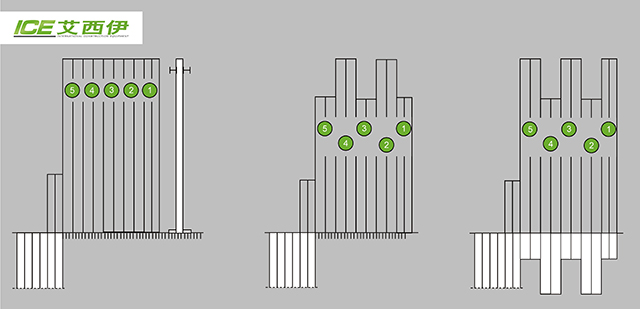

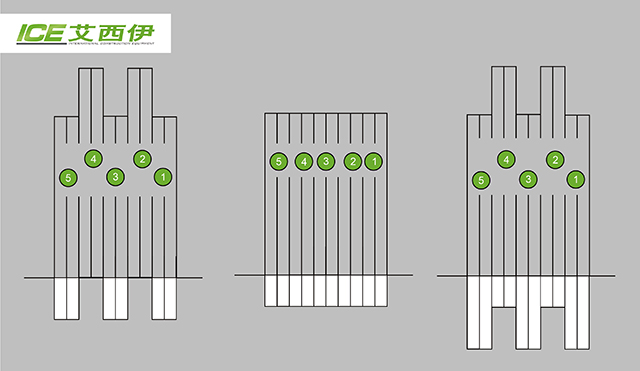

In difficult soil conditions panel installation combined with staggered driving is recommended.

The piles are installed between guide frames and then driven in shortsteps as follows:

piles 1, 3 and 5 first; then piles 2 and 4.

If the soil is very dense sand, gravel or rock, piles 1, 3 and 5 can be reinforced at the toe. In this case, these piles are always driven first and piles 2 and 4 in the second stage.

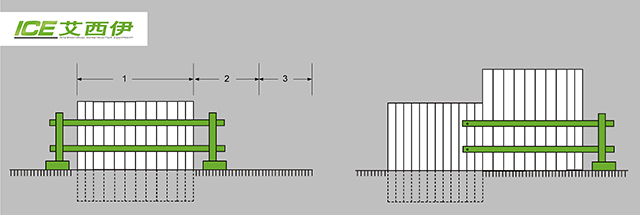

1.4 Driving of combined walls

Combined walls are piled walls which comprise high modulus components interspaced by much lighter sheet piles. The high modulus components known as king piles can be tubular, box, bearing or other

types of fabricated piles.

It is essential that a stable, heavy, adequately rigid and straight pile driving frame adapted to suit the length and weight of the piles is provided.

The king piles are located in position in the frame by welded bracket guides which take into account width tolerances.

Driving of the king piles must be carried out with extreme care in order that they are embedded straight and vertical, or at a prescribed batter, ensuring that they are parallel to each other and at the required spacing.

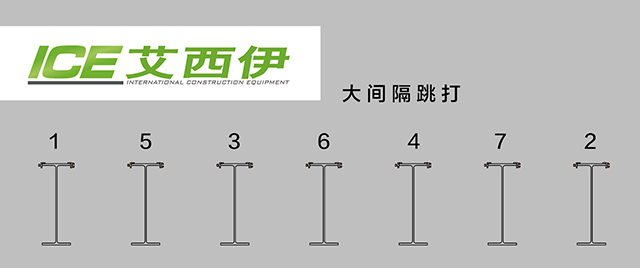

The driving sequence of the king piles must ensure that the pile toe encounters compacted soil uniformly on its total circumference and never on one side only.

This is achieved by driving in the following sequence:

1 - 5 - 3 - 6 - 4 - 7 - 2 (large driving step).

At least however, the following sequence should be observed:

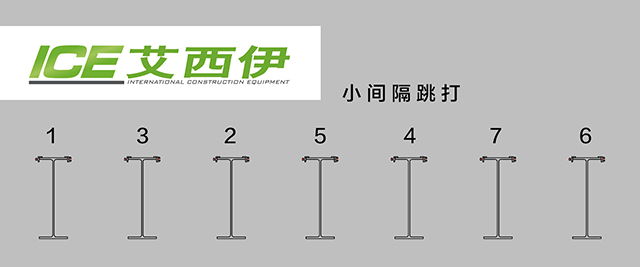

1 -3 -2 - 5 - 4 - 7 - 6 (small driving step).

In general, all of the king piles should be driven in sequence to full penetration without interruption. Following successful completion of this the intermediate light pile sections can be pitched and driven. During the pitching and driving operations of the king piles a constant check should be made, using theodolites, of their alignment along and normal to the wall.

When the guide frames have been removed a final survey must be made to ensure the deviations in the distance between the king piles are within the acceptable tolerances, so as to allow the installation of the sheet piles. However, if the deviations are outside the specified or practical tolerances then either the intermediate piles have to be adjusted or the king piles extracted and re-driven.

To overcome difficult driving conditions it may be possible to use jetting, excavating inside the king piles or any of the ground pre-treatment methods normally adopted for sheet piling.