Sheet pile solutions are gaining in popularity all across China because they help solve the following common deep foundation issues all users of diaphragm walls face:

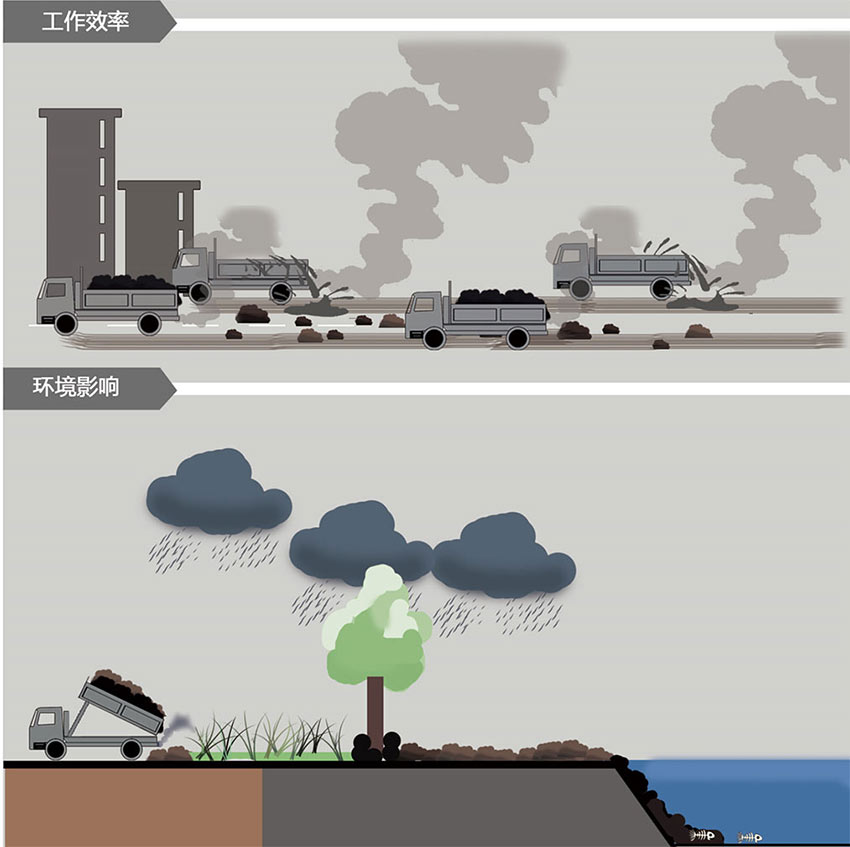

1. COMPLYING WITH BENTONITE POLLUTION REGULATIONS

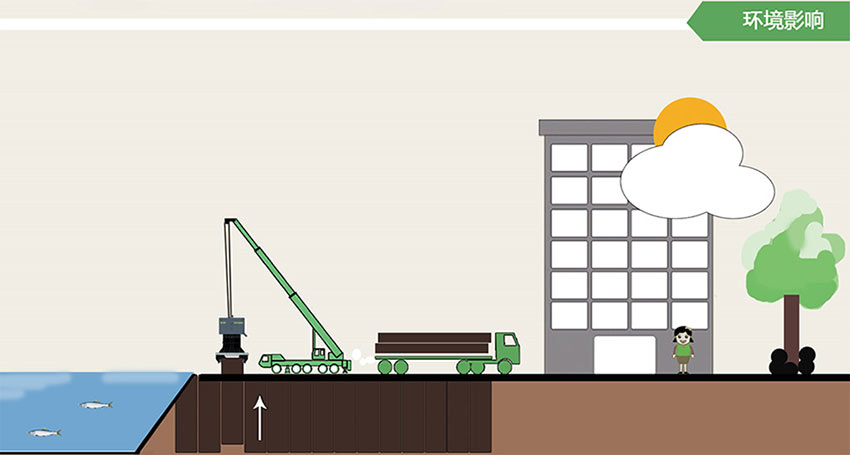

In order to make our environment more livable new environmental protection guidelines are introduced. One of the latest potential sources of pollution to be targeted is construction mud also known as Bentonite. Bentonite is widely used in trenching to build retaining walls at construction sites. This construction mud is now being black listed across China because the incorrect disposal of the bentonite pollutes waterways and the transport of the mud generates dust and exhaust fumes from trucks in inner cities. Shoring up excavation pits with sheet piles is a green foundation method that uses zero bentonite so no dust and mud waste are created.

Using sheet piles instead of a diaphragm wall instantly eliminates bentonite from your project. Avoided problems don’t need to be mitigated!

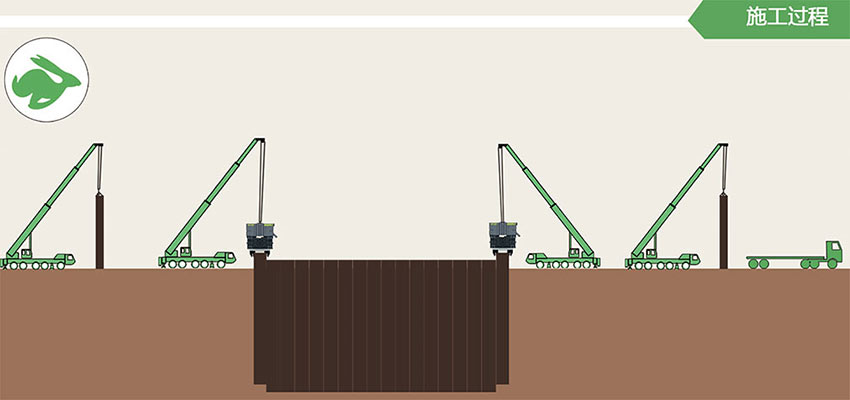

2. REDUCING PROJECT DURATION

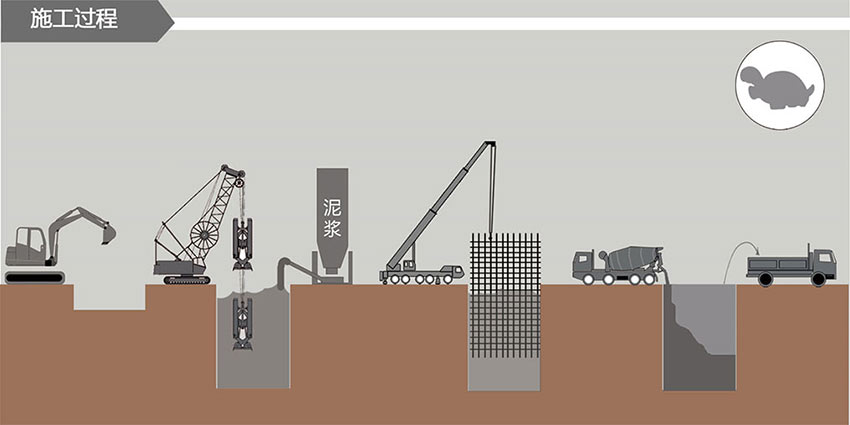

Time = Money. The building of a diaphragm is a complicated slow and labor intensive process. Driving and extracting sheet piles with a hydraulic vibratory hammer for retaining walls is a very fast method that reduces time to completion and therefore saves significant cost. Setting up all the equipment required for diaphragm walls takes many working days and assistance from hoisting cranes. Coordinating all the different worker teams and the arrival of bentonite and concrete trucks adds to your burden. Sheet pile walls are installed with just the help of a crane and a hydraulic vibratory hammer so your time is spent on finishing the job instead of preparing for it. The sooner you finish your project the quicker you can start the next. Working with sheet piles helps you reach much higher utilization rates of staff and equipment and get a better return on investment.

3. EXPENSIVE EQUIPMENT REQUIREMENTS

Building a diaphragm wall needs a long inventory of equipment and materials while sheet pile retaining walls are built with just a crawler or mobile crane and a hydraulic vibratory hammer. The sheet pile solution reduces raw material needs (bentonite steel reinforcement cage concrete) and equipment (bentonite plant concrete pump truck grab excavator hoisting crane) and reduces construction time (reducing labor cost diesel). Lower capital investment means better prices for the developer and a fair margin for the contractor.

4. NARROW WORKING SPACE RESTRICTIONS

If your site’s boundaries are close to existing buildings roads or along a waterway sheet piles allow you to work right up to the boundary. When using a resonance free vibratory hammer you can install the sheet piles without disturbing the neighbors and causing damage to existing buildings or buried utility lines.

5. CAN'T BLOCK OFF TRAFFIC

Along busy road sections the impact of construction work on traffic flow should be minimized. Using sheet piles like the U-pile or AZ sections that use up little space traffic flow is uninterrupted. This means permits for traffic diversion do no need to be applied and waited for.

6. RETAINING & BEARING CAPACITY BOTH NEEDED

Sheet piles have a dual function of load bearing and retaining function. For projects that require both a water tight retaining wall and a load bearing function like overpasses and parking garages AZ sheet piles are your best choice. The sheet piles are installed rapidly and sheet pile companies offer services that calculate your projects material requirements so that you will use the correct and most cost effective sheet pile solution for your project.

WHAT PROBLEMS CAN SHEET PILES HELP YOU OVERCOME?

Sheet piles and pile driving equipment are widely available for sale and rental across China. In recent years alongside the rapid urbanization of China the sheet piling business has matured. Many new and attractive solutions are now available solving earlier drawbacks of the sheet pile retaining technology. Sheet piles are now wider longer and stronger than ever before allowing for quicker installation and deeper excavation. With the introduction of ICE hydraulic vibratory hammers and resonance free hydraulic vibratory hammers work efficiency has increased and work in heavily urbanized areas can be tackled without problems. Follow our WeChat group to keep up to date with the latest market developments. Get in touch with us when you are ready to make the switch from diaphragm walls to sheet piles! We’d love to hear from you.