This article is the second on Shanghai Zhongtai‘s foundation construction job at Shanghai S3 expressway. Zhongtai used the ICE 14NL impact hammer to drive steel tube piles with a diameter of 700mm and a length of 57 meters. The bottom of the piles were fitted with welded x-plates that were inserted to increase the bearing capacity of the piles; instead these plates caused a soil plug that proved too much for the 50RF vibratory hammer to displace and the piles didn’t reach final depth. The 14t impact hammer was brought in to drive the piles to final depth. The 14t hammer, fitted with an extra 2 ton drop weight worked effortlessly.

Compared with the diesel hammers, the ICE impact hammer’s noise offers a 15-20 decibels reduction. Also, there is no pollution of oil mist and tail gas as produced diesel hammers. A hydraulically powered impact hammer can control the stroke and frequency of the blows.

1. On-site installation and commissioning by ICE service engineers

2. mobile crane lifts the hammer into piling position.

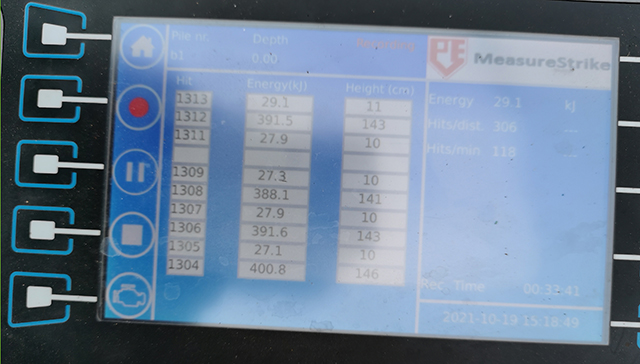

3. On-site screen monitoring of various piling data (the number of hammer blows, drop height and the energy brought into the pile which translates into a bearing capacity reading.

With the introduction of ICE hydraulic impact hammers in China, the replacement of diesel hammers by new technology has been accelerated. At present, the construction requirements for green and environmentally friendly construction advocated are becoming more and more stringent. Many places have introduced bans on the use of diesel hammers. The hydraulic impact hammer has little impact on air quality and the noise is less loud and irritating.

We do not recommend welding plates at the bottom of the pile to increase its bearing capacity. Instead, we recommend that bearing capacity is optimized either by controlling the frequency of the vibratory hammer during pile driving, or by injecting grouting around the pile tip.

If you have a similar construction project, please do not hesitate to contact us directly! We hope to discuss your project needs with you and help you choose the right hammer.