How difficult can it be? An OEM engine, a pump from a famous brand, a gearbox that looks new and shiny and a mouth-watering spec sheet. But then the equipment arrives on site, and it just doesn’t quite work as advertised.

Hydraulic vibratory hammers are powered by diesel powered hydraulic pumps, that provide oil flow that turn eccentric weights, that generate vibration amplitude. Measuring the flow and pressure will tell you if the hammer is able to work as specified. In practice this is hard to check for the typical user, there are very few flow meters that can handle the output of a power pack.

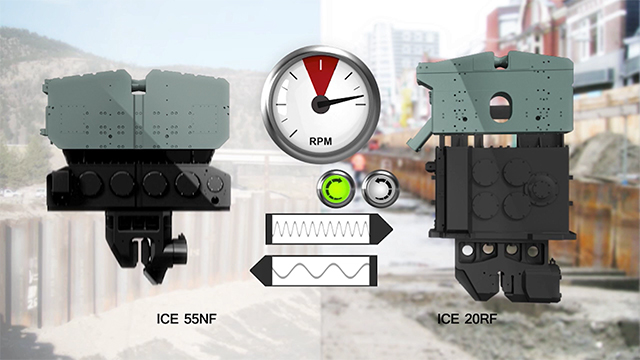

【A simple way to check if your vibro hammer supplier is cheating you】

The most straightforward way is to test the following with a handheld device:

1) The rpm of the vibro, if it meets the data in the spec sheet you know you’re working with the right equipment for the job.

2) The temperature of the bearing covers, it will tell you how well the power pack is cooling the oil which will ensure optimal performance and lifespan of the whole set.

If the RPM doesn’t meet the specification, it means you will not be able to generate the amplitude you need to get the pile down. One way ICE ensures our hammers reach the spec is by providing sufficient liters of hydraulic flow at high pressure, and by choosing the correct hydro motors on the hammer.

Why is it important to have high RPM? It ensures proper liquefaction of cohesive soils, and ensures the vibration travel just a short distance from the pile surface minimizing the vibration impact on the surroundings.

Practically this means that to keep the vibro operating at its specification it is necessary to pay attention to the power pack’s pump and engine. ICE’s power pack design is optimized to meet these requirements: a variable pump and effective cooling of the power pack offer optimum working conditions for the pump.

While it is common practice to choose a larger vibratory hammer when a pile meets refusal, the data (see article under selected further reading) shows that for heavy driving conditions it could be more beneficial to increase the power supply and keep the hammer unchanged.

To compare different hammer models or brands you can determine the ratio [max centrifugal force kN hammer] and [engine max power kW of the power pack] which will predict the performance of the equipment. If you are unsure about the accuracy of the specs provided by a supplier, you can easily check the frequency of the vibro with a handheld RPM-meter to see if it matches the data provided by the manufacturer.