This week we present some breakthrough results from an ICE user at a test pile project at Lemen Windfarm:

A single ICE 250NF vibratory hammer equipped with just two clamps drove 260t piles 42 meters into the sea bed. Thereby exceeding the driving depth prediction by 17 meters and shortening the project completion by many days.

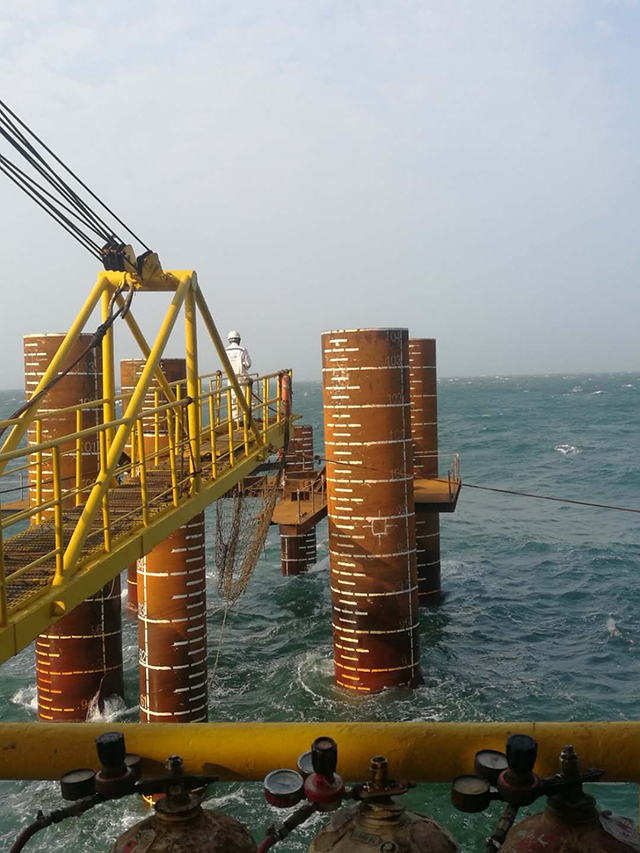

Guangzhou Salvage bureau has successfully completed the installation of test piles at Lemen Offshore Wind Farm, off the coast of Shantou in Guangdong Province. Four anchor piles with a diameter of 2.4 meters, wall thickness of 25mm, length of 104 meters and weight of about 160 tons, one main pile with diameter of 2.4 meters, wall thickness of 40mm, length of 110 meters and weight of about 260 tons, and two base piles with diameter of 1.5 meters and wall thickness of 40mm and weight of about 60 tons were installed. Pre-piling was done with a single ICE 250NF vibratory hammer.

Guangzhou Salvage Bureau commissioned the salvage vessel Huatianlong for the job, choosing a hydraulic vibratory hammer for positioning and pre-piling the pile to a depth where it can self-stabilize, then using an impact hammer to drive the pile to design depth. Handling was simplified by attaching the hammer to the pile prior to upending. The 250NF was equipped with two 350T clamps (weighing 3 tons each), simplifying the positioning of the vibro on the casing. The clamp position on the beam is secured with a hydro-lock. The hammer was turned vertically and positioned on the pile within five minutes, many times faster than was previously possible with tandem equipment. During upending the weight of the pile was carried by two lifting lugs welded on to the pile.

The water depth was 25 meters, the pile was to be driven at least 20 meters into the silty clay layer to guarantee self-stabilization. To assist the client in selecting the correct equipment ICE performed a pile driving prediction. According to the analysis, the ICE 250NF would be able to drive the 260t pile to a depth of at least 25 meters, meeting the requirements set by the design. The soil profile was as follows: coarse sand, silty sand layer, silty clay layer, and then reach the medium sand layer.

The 250NF (eccentric force 537t, 1,536-horsepower power pack) needed just 20 minutes to drive the 260t pile 42 meters deep, 17 meters deeper than predicted. The pile driving speed of the vibration hammer is mostly based on the release speed of the crane, and controlled to meet requirements of verticality, affecting the pile driving speed to some extent. The representatives of the developer, project managers and constructors who watched the scene expressed their approval satisfaction. The pile was then driven another 30 meters to design depth with an IHC 1200 impact hammer, leaving 6 meters of pile above the water line.

Driving the pile deeper than previously thought feasible by the software calculation, meant that the pile had better wind resistance and self-stability ability before the start of percussive piling. After these results, Mr. Hu, the project manager, felt confident in the performance of the ICE hammer and adjusted the construction plan, shortening the construction period of the whole project by several days. Time savings were made because of easy positioning and upending and reducing the pile length that needed to be driven by impact hammering by 17 meter.

In ICE’s experience, the accuracy of the geological report is the most important factor influencing the results of the piling driving analysis. More and more customers have realized this and put forward higher requirements for the accuracy of geological reports provided by the developers.

What are the key lessons from this demonstration project? Vibratory hammers such as the 250NF can drive piles deeper and faster than competitive offerings; upending the pile with the vibro connected on the pile leads to increased safety and significant time savings.

Before the start of construction, the project manager worried about the performance of the vibro. Previous experience with long and heavy piles had taught them to expect a lot of bolt failure, resulting in safety hazards, lots of downtime, and low driving speed. After the piling, he said: “ICE has lived up to its international brand name, its product performance, design advantages and stability have exceeded our expectations, and helped shorten our construction period.” Working with a single hammer, not a tandem construction makes handling easier. It reduces total weight, halves the number of hydraulic hoses, reduces fuel consumption and takes up less deck space.

ICE is a flexible company that provides customers with a variety of piling solutions and technical support. We are willing to support your specific project requirements as much as possible. Please pick up the phone and contact us now.