While U piles and combi-piles are the most common sheet piles in this part of the world there is a sheer endless variation possible with these basic steel elements. It's a bit like Lego, the basic elements allow your imagination to run free and to experiment in obtaining the highest efficiency in installation speed, material cost, or lateral bearing capacity. Please read to the end to see the safety information.

ICE has been supplying vibro equipment since 1974 and has assisted with many of the sheet pile innovations with tweaks to our clamping system. Today we would like to share some of these innovations with our readers. Which one do you want to try?

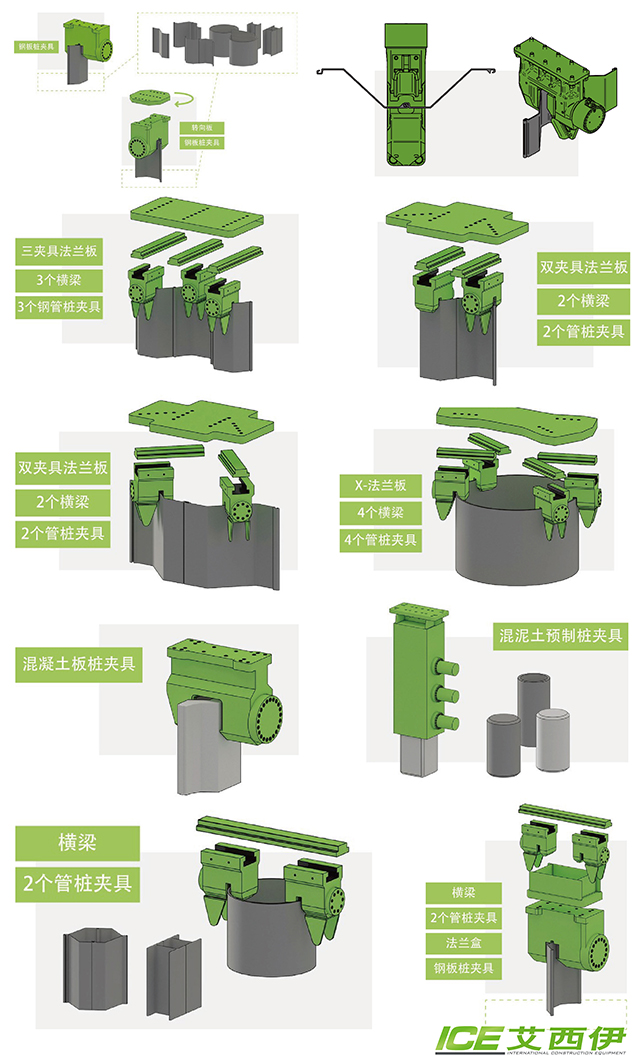

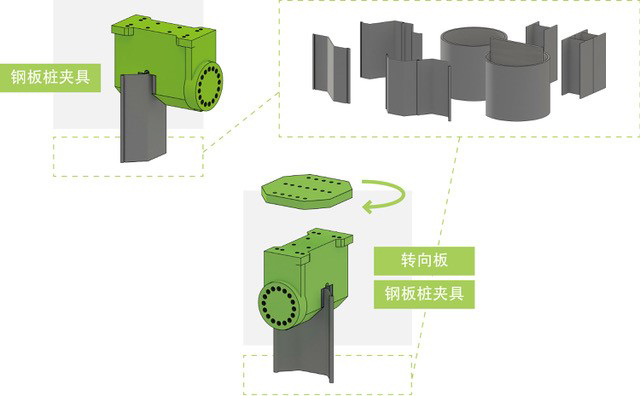

The clamp is normally fitted on the same plane as the hammer to ensure the hammer can drive in between two piles. A turn plate allows our single clamp to be turned 90 degrees, this allows the hammer to drive piles close to a wall. The turn plate is fixed to the hammer with bolts. We recommend using a hydraulic wrench tool to make sure the bolts have the right torque.

Our single clamp can simultaneously drive two piles. Our TU-series of sheet pile clamps are fitted with a jaw plate that can slide over a U or AZ sheet pile interlock, allowing the operator to drive or extract two sheet piles simultaneously. This is a very popular practice in Europa and the America’s. It can double the daily installation rate. ICE hammers have adequate driving force to drive 6m, 9m, or 12m sheet piles in pairs. The two sheet piles need to be crimped so that they become one. Even excavator mounted hammers can do this, just check the video below where the 8RFB drives two piles at a time.

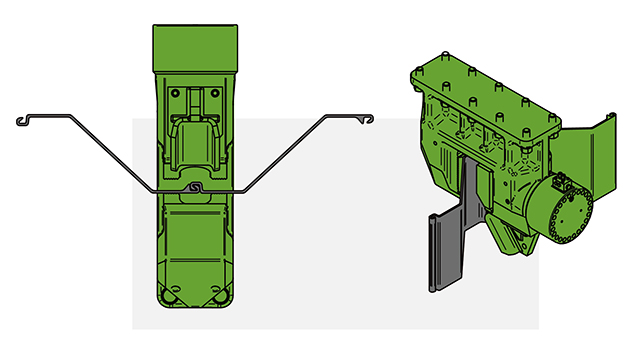

Triple sheet pile clamps. A typical application for this set-up is driving sheet piles for combi wall. The casings are first driven and then the intermediate space is spanned with the three sheet piles. As the three sheet piles have some slack, it is easier to drive them down in a set than individually. Recommend equipment: Resonance free equipment such as36R, 50RF, 70RF

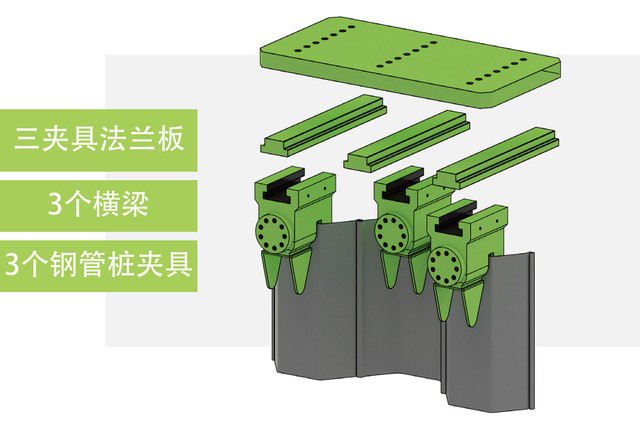

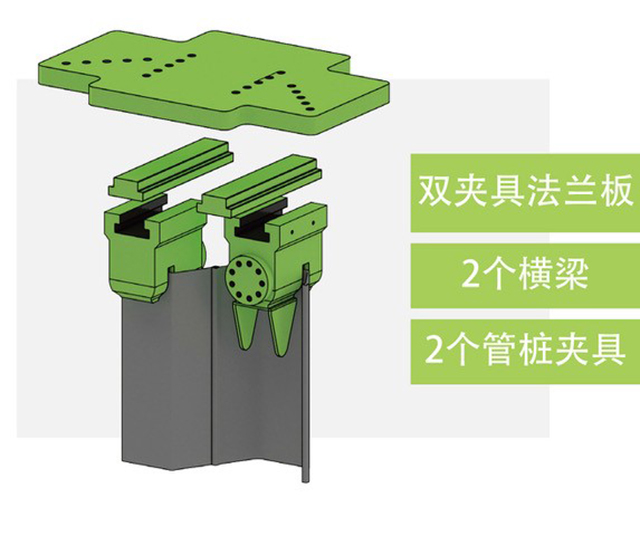

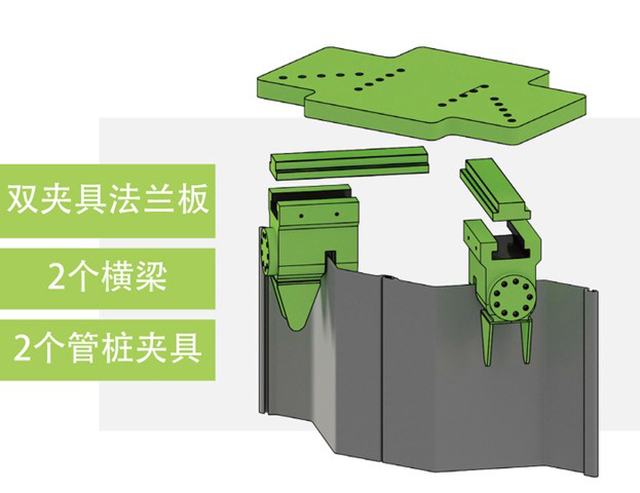

Double clamping plate for driving two U piles simultaneously, this doubles installation speed. If you already own a TC clamp set for driving casings, you could change the concave jaw plates that are needed for casings, to flat jaw plates that give optimal grip for sheet piles.

Wide AZ profiles benefit from two clamps at 45 degrees angles. This allows for more control of the thin walled AZ profile.

x-plate with 4 clamps: allows driving of XL casings, or casings with a thin wall thickness.

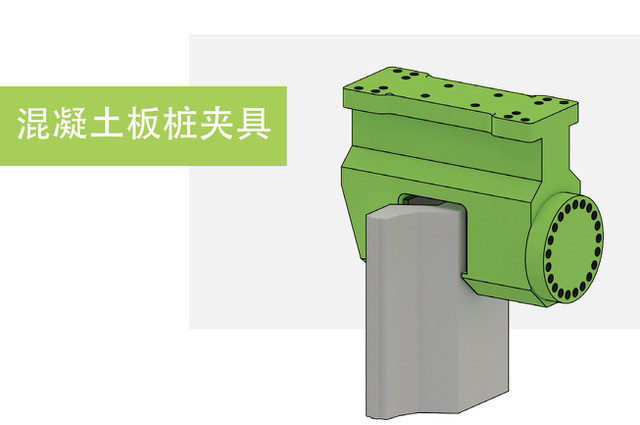

The concrete clamp is designed for vibrating concrete, with wide clamp opening, extra-large jaw plates and lower clamping force to ensure the pile is not damaged during installation or extraction. We recommend using resonance free vibratory hammers for the installation of concrete as it will avoid the resonance that could damage the pile.

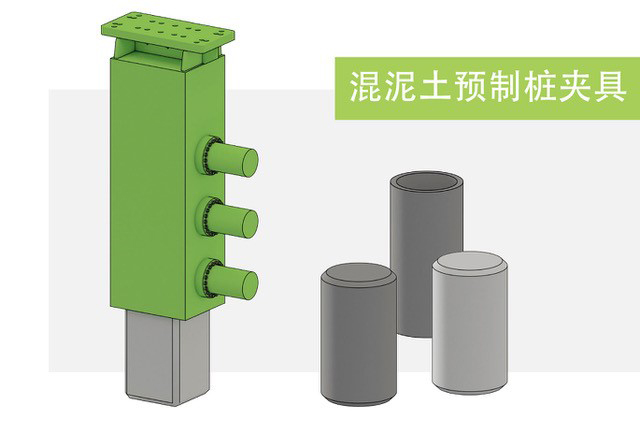

The TP clamp is designed to drive and extract square and round wooden or concrete piles. The clamping force is distributed over a maximum of three cylinders, preventing clamping damage to the pile. Driving closed bottom piles with a vibratory hammer is only possible for short piles in soft soils. The maximim diameter of the pile is 520 x 520 mm.

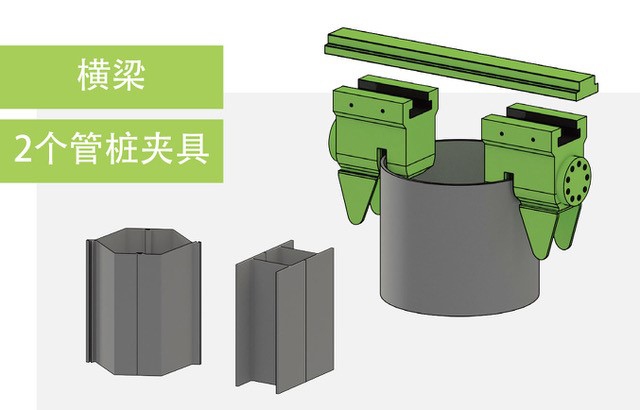

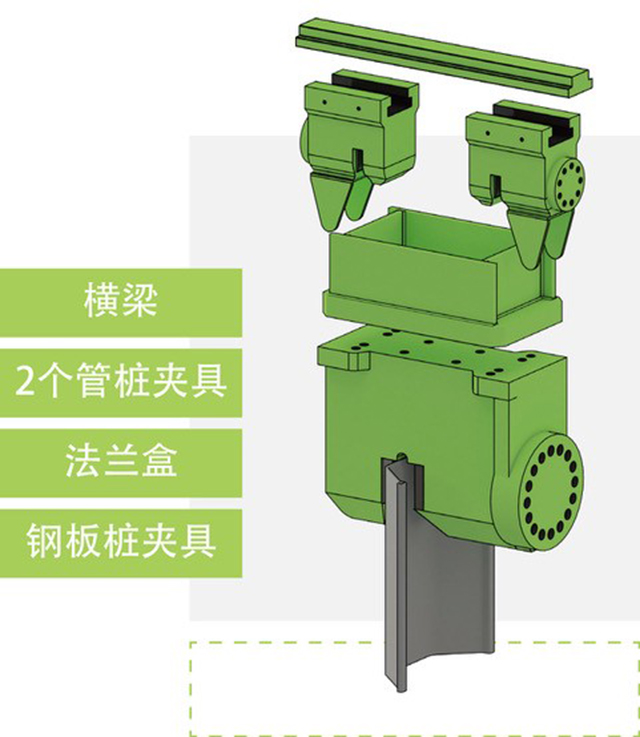

Double clamps on a beam are widely used for driving casings, but they are also a good choice for driving box piles (either the H-beam variety, or the U-box variety).

The flange box is designed for jobs where both sheet piles and casings need to be driven alternatively by the same hammer. Not having to dismount the beams and the single clamps saves the operator a lot of time.

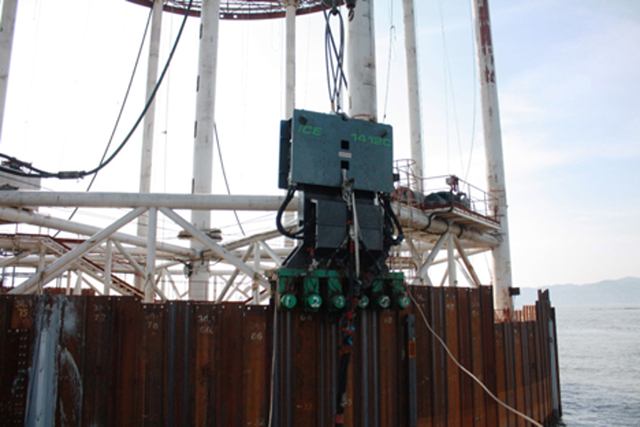

What about 6 piles at once? It has been done by China Harbor Construction. They equipped their 1412C’s with 6 clamps to simultaneously drive 6 sheet piles at HK Macao Zhuhai Bridge Cross Boundary Island.

This article is already super long, so we leave you with a quick mention of some other specialized piling equipment available for your sheet piling jobs; the side gripper, pile press.

VIDEO Side Grip: This video shows our design for side gripping piles, this machine can work in load head space.

VIDEO Pile Press: This video shows the pile press, mounted on a piling rig it can install 4 piles simultaneously without vibration.

Safety notice:

ICE clamps are designed for these applications with your safety in mind. Clamping force is 1.2 larger than the eccentric force of the hammer. Our clamps are not welded but are made in one piece from a mold. The clamps are heat treated before they leave the factory and tested before they are shipped to the customer. The beams and turning plates designs are checked by our structural engineers to ensure safe operation. We advise our users to use a hydraulic wrench to fix bolts at the correct torque needed for the turn plates, beams and clamps. Please don’t try this at home without our assistance.

Our team in Shanghai can help you realize the techniques discussed in this article. Get it touch to get smart.