Introduction

Green construction! Buzzwords come and go, but the underlying concern has been consistent: the construction industry wants to reduce construction impact on the environment and make cities more livable. The industry wants to reduce bentonite and concrete use, reduce construction time and lower costs. Many of these hot topics touch on foundation construction method choices. Steel retaining walls are the foundation of the circular economy!

METHOD

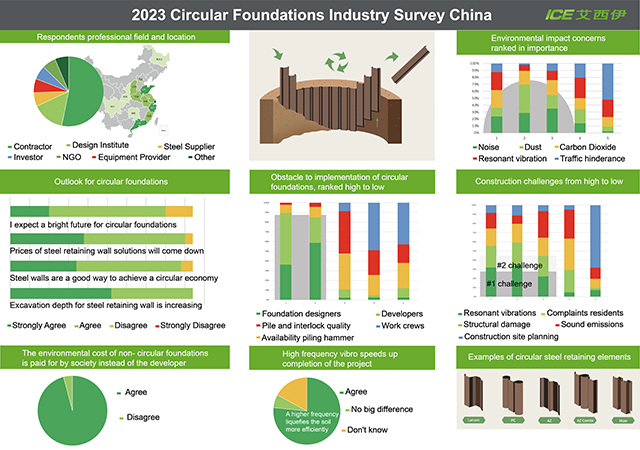

To learn more about circular steel retaining wall’s role in the circular economy, we set-up a survey to uncover the respondents’ main concerns and challenges for circular foundations, as well as the main benefits of the circular foundation method.

The participants of the survey were told that our aim was to test the proposition:

**Popularizing steel retaining walls to supersede diaphragm walls to meet circular economy objectives, an excellent choice for all involved and good for the environment as well.

DISCUSSION

Analyzing the survey data and referring to scientific publications related to the topic, the following picture emerges about the benefits and challenges of circular foundations which the authors discuss below.

Steel retaining walls are quicker to construct then concrete retaining walls, reducing nuisance from noise, dust, and construction vehicle movements in urban centers during the period of construction, while also allowing the developer to move the handover date of the property forward. Circumventing possible damage to structures (i.e., buildings, tunnels, utilities) due to peak resonance vibrations in the natural frequency of these structures are the main concern. Choosing appropriate equipment, such as resonance free vibratory hammers and static piles press machines, and working with recognized construction methods, all of which are readily available in the domestic market, the safe installation and extraction of temporary steel retaining walls is ensured.

The main environmental concerns for foundation construction ranked noise and particulate matter as top concern. The construction equipment needed for the installation of steel retaining walls produces no significant sound emissions of itself and due to the fast installation pace further reduces sound emissions [1,2]. The steel retaining wall method requires no excavation of soils or use of drilling muds, so particulate emissions are very minimal [1,2]. Two thirds of the respondents included CO2 emissions in their top 3 concerns. It was striking to the creators of the survey that CO2 emissions were top concern for the expert response, even though it is an official government target for carbon neutrality by 2060, carbon emission are infrequently discussed in informal conversation about foundation choices.

Research has been published by Cai et al. (2022) that estimates that, due to the reusable nature of steel foundations elements, the carbon emission of steel retaining wall solution is about 14.3% that of that of a permanent reinforced concrete wall structure, and the steel retaining walls energy consumption throughout its lifetime is about 16.2% [4].

Limited awareness among designers and developers about the potential of steel retaining walls was seen as a major barrier to implementing a circular-based retaining wall. Steel retaining material and installation specialists indicated a gap between themselves and the foundation designers and real estate developers, that impacts the proper costing of the steel retaining wall versus concrete retaining walls. Incorrect costing creates false advantages for traditional concrete retaining wall designs, which is a grave concern at a time when the industry is rising to the challenge to meet more stringent national Carbon Emission targets. More research and practical exchange is recommended between the developer and the contractor; to resolve each side’s concerns, such as can be summarized as unfair costing vs. suboptimal material choice and installation techniques. Encouragingly, contracting company respondents acknowledged as much in this survey. For circular retaining walls to be readily preferred by owners, contractors need to resolve concerns of construction quality, by selecting high-quality steel solutions and the most suitable equipment over short-term considerations.

When asked for the main competitive advantage in circular foundation, respondents state technical expertise and advanced installation methods as the main drivers of their competitive advantage. Circular foundations walls have limitations for excavation depth currently at 15 meters, and they can only be installed in granular soils. Expertise in working with soil analysis reports, pile driving predictions, selection of vibrating protocols (at differing frequencies [3]) and pile pressing protocols (with addition of boring or water jetting) are what bring success. Verticality requirements during pile installation can be achieved by choosing hot-rolled steel interlocks, employing pile positioning frames and inclination sensors. Contractors that manage these parameters well can deliver deep foundation pits that be competitive and profitable.

The respondents indicate an overall optimistic outlook for the wider implementation of steel retaining walls. Quality and safety of the retaining walls have room to improve up, with wider availability prices will come down, and excavation depth will increase, while stating that the introduction of supportive green building regulation codes will be a major catalyst for the popular implementation as it can expose false competition with traditional concrete methods. We hope the results from this survey will embolden more design institutes and developers to opt for steel retaining walls where technically feasible and that government policy will support and encourage the use of the steel retaining walls in whatever varied form they are available!

The foundation industry knows it can make a real contribution to reducing environmental impact by implementing circular foundations. This is not feel-good tokenism or environmental greenwashing. Steel retaining walls maybe all but invisible to industry outsiders while they are doing their work, and they leave no trace after completion of the project, but this is where the low hanging fruit for decarbonizing the industry is to be found.

CONCLUSION

The carbon dioxide emissions of circular steel retaining walls have been estimated to be about 14.3% of that of permanent diaphragm walls. Materials and installation tools are readily available for circular foundations, but awareness of the benefits of the method is lacking with design institutes and developers who are more focused on the perceived challenges. This paper counters many of the perceived drawbacks of the reusable retaining walls with survey data. The authors of this paper invite more discussion on this topic, in particular in addressing the following factors that limit the wide scale adaptation of circular foundations:

• over-specification by design institutes bloating the true cost of the method

• underestimation of re-usage cycle potential

• subpar installation crews increase failure

• other retaining wall methods unfair non-attribution of environmental cost to society