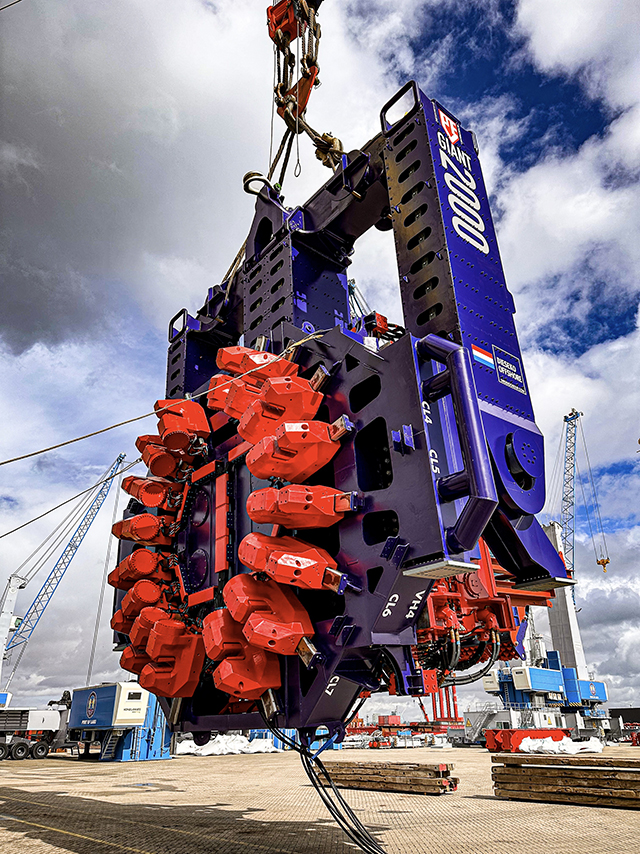

You will be completely overwhelmed when you see this offshore machine for the first time. It is humongous. At once familiar, yet at a glance obviously so full of innovation. With dimensions of approximately 10 x 10 x 8 meters and a weight of 425 tons, this is ICE’s biggest vibratory hammer the world has ever seen. The four 500 kgm gearboxes provide 2000 kgm Eccentric Moment and dependably generates 44,000 kN of centrifugal force at 1400 rpm. That translates to a frequency or 23/ second of up-and-down movement of pile and dynamic weight to overcome soil friction and get the pile to depth.

MONOPILE INSTALLATION

The ability to handle monopiles arriving at site using the GIANT 2000MU vibratory equipment is a great benefit for installation contractors. Dieseko has developed an active upending tool with this in mind. There is no need to separate the upending and pile driving operations as required when using impact hammers. The obvious benefits being a continuous process from stabbing the monopile, to up-ending it, and then vibrating the pile to the final penetration depth.

NOW YOU CAN:

Drive monopiles at the speed of pile positioning frame piles

Achieve accurate positioning without pile positioning frame

Correct inclination while driving and eliminate pile runs

Work with much lower noise levels

Reduce fatigue due to different energy impact, increasing the design life of the mono piles

Design piles with thinner wall thickness

With such glaring advantages of vibratory piling, ICE is of course not the only company to provide this type of solution! Why do we think you should choose to work with our equipment?

These are the advantages of our offer:

In China, as in the rest of the world we have local presence and local service.

The Giant is technically unique because it has positioned the elastomers inside the patented up-ending arm. This brings three major unique advantages:

Even load distribution

Easy customization of the dynamic vs static weight which impacts driving performance.

Hoses management made simple and durable.

1. The elastomers are always loaded in the same direction and not torqued in different directions, irrespective of the position of the hammer, whether during upending or in driving position.

2. This design allows our us to change the isolation efficiency and control of the vibration propagation towards the crane. For heavier piles or harder soils, you might end up with a need for a different number of elastomers resulting in a better isolation efficiency and thus less risk on crane vibrations. In other words, we can change the spring characteristic of the hammer easily, as the elastomers can be reached without having to dismantle anything. Also, in case of elastomer damage, elastomers can be exchanged on board of a vessel inside an hour. If the pile is heavier, it will cause higher reaction forces (pile to hammer) as a result of the generated centrifugal forces. This will need a stiffer spring rate to prevent the static part to excite while amplitude might be similar.

3. As the upending arm does not change direction at any time during operation and the hose chutes are connected to the static part of this arm, the orientation of the hoses coming from the hammer is always the same, and will not move relative compared to the arm. So, the Giant can be operated it with a fixed set up; e.g.: hoses that run always towards the crane works best, no difficult 90° orientation shifts of the complete hose package during operation. This means no work plan for hose management needs to be devised for each mobilization.

For those of you who already own an ICE 250NF or 500NF with power pack and clamps reading this story, you are already on the way to building your own GIANT with these common components. In the coming weeks we will be contacting our contacts in the offshore wind industry. If you don’t want to wait your turn, schedule an appointment with our team now!