Last year we summarized a Leuven University article for our website, which demonstrated that while it is common practice to choose a larger vibratory hammer when a pile meets refusal, the data shows that for heavy driving conditions it could be more beneficial to increase the power supply and keep the hammer unchanged. The customer application we are sharing below clearly shows how this works out in practice. For the construction of the Shanghai-Suzhou-Huzhou railway line 39m long steel casings were installed by a medium sized 55NF vibro hammer and a powerful ICE 600 power pack.

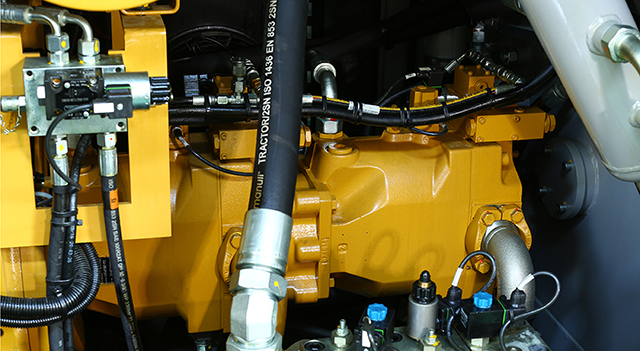

The power pack functions like a heart, it is connected by hoses (arteries) to hammer and clamps (the limbs and muscles) and drives the whole body. Practically this means that to keep the vibro operating at its specification so that the pile overcomes soil friction and is installed, it is necessary to pay attention to the power pack’s pump and engine. ICE’s power pack design is optimized to meet these requirements: a variable pump and effective cooling of the power pack offer optimum working conditions for the pump.

Choose a light vibro and a powerful hydraulic power pack!

The 39 -meter steel casing piles chosen for the Shanghai-Suzhou-Huzhou railway had a 630mm diameter and were driven in three sections. The soil layers after the 30-meter mark were complex, so the client worried about driving the third and final section of the pile with a medium sized hammer. But, bringing in a larger hammer for the last section would add to the construction cost which was unacceptable. The decision was made to use the 55NF powered by 600 power pack which offers 600 liters of hydraulic flow at 350 bar pressure to complete the whole job. With this power-combination the hammer was sure to meet its spec at 171t eccentric force at 1700 RPM and easily get the pile in place. The first two pile sections went in with only 45% engine load, the third section met more soil resistance due to the complex geological conditions but was no real challenge for the 55NF – 600PP combination. Even the third section was installed in under 10 minutes.

Did you know that to compare different hammer models or brands you can determine the ratio [max centrifugal force kN hammer] and [engine max power kW of the power pack] which will predict the performance of the equipment?

Why bigger vibratory hammers aren’t always better is easily understood: A vibratory hammer is made up of two parts: a dynamic vibrating part (the gearcase, clamps, 50% of the weight of the elastomers) and the static weight (the yoke and the other half of the elastomer weight). The heavier the dynamic part the more eccentric weight is consumed by moving the dynamic weight and less remains to create amplitude to liquefy the soil. This tends to create a vicious cycle of ever-increasing weight to create more amplitude. That is why ICE is so focused on offering the lightest hammer for each job as it will give the best result. Get in touch to right-size a hammer for your job!