In this article you will learn about four tools for driving offshore wind farm foundations. ICE vibratory technology answers the call for innovative hammering, lifting and drilling solutions without the environmental damage typical to the offshore piling industry. Our pile driving solutions combine low noise with easy handling and driving time savings.

▏Single unit

The 250NF vibratory hammer is one of the largest single hammers available to our clients in China. It offers 537t eccentric force and can handle piles with a weight of up to 135t and a diameter of up to 5 meters. In China it is often used for driving and extracting of the legs of the mono pile positioning frame. For each mono-pile the vibro is used 8 times, reliability is paramount. The 250NF is powered by a fuel efficient 1600 power pack (1130kW). The hammer can be fitted with positioning tools to guide the clamps onto the casing efficiently, ask our sales team for details.

▏Tandem

The tandem concept is a flexible system that works well over a wide range of small to medium sized casing diameters and lengths. Two separate hammers are joined up to work as one system, nearly doubling the driving force of the hammers. In China ICE has sold a 200M-tandem and 170NF-tandem for casings with a diameter up to 5 meters.

The first generation of tandem hammers placed hammers side by side, synchronizing gearboxes with shafts and weighty frames. The new generation of tandem hammers is a stacked tandem. It is just like adding another slice of meet to a hamburger. A second gear box is added on top of the first to double the eccentric force of the hammer. This type of tandem hammer is much lighter, resulting in greater amplitude for the pile. It is also much easier to position and operate. Assembling and disassembling of the unit is much quicker than the traditional way of connecting the gear boxes of two separate hammers side to side.

The second generation of tandem equipment allows our users great flexibility in the set-up of their equipment. The upgrade is possible for the following models: 130NF, 150NF, 170NF and 250NF.

▏Upending technology – lift and drive

The patented 300MU has earned its reputation as a time saving power tool. In 2013 on board the jack-up installer “Innovation”, the Dieseko Group’s vibro hammer lifted and drove the 240 piles anchoring tripod foundations at Germany’s Global Tech 1 wind farm. These massive swiveling upending vibro hammers can lift casings from a horizontal deck position into a vertical driving position in one fluid motion. This eliminates the need for a separate lifting tool and reduces handling time; leading to savings in operating cost and deck space.

The Global Tech 1 project was the first commercial application of Dieseko’s upending design. The client’s foundation piles ranged from 48 to 70 meters in length with a diameter of 2,5m, and a total weight of up to 220 ton. The vibro was used for positioning and preliminary driving。

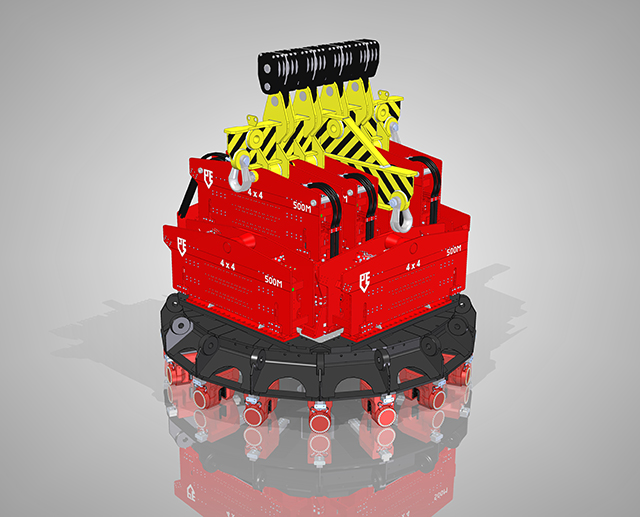

▏Giant Modular Vibratory Hammer (patent pending)

In addition to these concepts, we developed the ‘Giant’ as our modular 43,000kN vibro hammer for driving the largest monopiles. The PVE Giant is a spectacular modular vibro hammer concept. The Giant is made of a single platform base to which the required number of individual gear cases can be added. The baseplate can carry a maximum of up to eight gear cases of 250kgm each, combining to a massive total of 2000kgm. This design is perfectly suited to for driving monopiles with a diameter up to 8m. The hammer is lifted on the frame and not on the gear cases allowing for a much compacter design than conventional hammer designs. The bottom plate of the module is fitted with sliding beams that allow clamps to be adjusted to the pile diameter after which the clamps are hydraulically locked to position.

▏Drilling past Vibrating Limits (patended)

Vibratory technology reaches its limit in subsea rock because vibro and impact hammers cannot penetrate dense, hard soil layers. Dieseko and drilling experts DDC (representing German manufacturer Aker Wirth) have joined forces to develop an innovative solution to overcome this challenge– a combination of vibratory and drilling technology for piles 8 m (or more) in diameter. The patented Vibro Drilling Concept integrates vibrating equipment and drilling equipment into one unit that is positioned on top of the monopile. Both tools are powered by the same hydraulic power pack. By combining vibro hammers and a drilling tool we are well prepared for different soil conditions. The tool is capable of driving monopiles or jacket foundations. The vibratory equipment will start up first and its goal is to vibrate the pile to the required depth. When hard soil layers are encountered the vibrator is switched off and the drilling technique is started. As soon as the hard soil layers are overcome, the vibrator comes back into action and continues driving. The time savings in this combined technique are considerable.

Quiet Innovation

The disadvantages of conventional hydraulic pile hammering are widely known. According to the North Sea Foundation “hydraulic impact hammering is the primary contributor to anthropogenic sound energy in the North Sea and can cause serious injury to marine life. With growing awareness of the environmental impact, regulators are increasing their HSE requirements for offshore wind parks. Piling sleeves and bubble curtains to reduce the impact of piling noise are now common in Europe. Vibratory technology has emerged as the most versatile and innovative alternative. Noise levels from vibratory hammer driving in the offshore wind projects show a Sound Exposure Level (SEL) result of approximately 140 dB at 750 m. These results comply with the latest – and lowest – noise regulations issued by Germany’s Federal Maritime and Hydrographic Agency (BSH).