One thing CHEC changed to increase efficiency threefold for its underwater deep compaction project in Ivory Coast.

What can you learn?

The port of Abidjan in Ivory Coast is undergoing massive extension to support the country’s growing trade activity and act as motor for the development of the country. The Ivorian government ordered the port to be built to exacting international standards. With the backing of the Chinese Central Government Belt and Road investment program, China Harbor successfully tendered for the construction work.

The chosen site’s ground conditions are complicated. The soil layers are soft, with low bearing capacity and require extensive ground improvement work before actual harbor construction can commence. The project designer set a SPT value of N-22 as the compaction target. To meet this goal the following method was designed: 18m of mud located at a water depth of 40 meters was dredged and replaced with sand. Hundreds of thousands of cubic meters of sand were brought in by hopper, and 40.000 linear meters of vibro compaction was ordered. Vibro compaction is a ground improvement technique that densifies clean, cohesionless, granular soils by means of a downhole vibrator that excites soil granules with vibrations, water or air jetting into a denser grid. With such an enormous task at hand and strict quality requirements the electric vibro compaction equipment that CHEC had brought along from China for the job were letting them down. CHEC made the decision to bring in an ICE V230 hydraulic vibroflot and managed to shorten the construction time threefold.

Threefold? Yeah right… how is that even possible I can hear you think? The electric equipment has some major difference other than the power source that affect the compaction performance: there is a big difference in the eccentric weights rotation speed which means a lot of energy is lost in resonance, which is unpleasant for the workers, and harmful to the crawler crane which suffers from the constant violent shaking of the boom. The electric vibroflots low driving force also limited the compaction depth to 4-5 meter on each pass, which meant that the entire 18m sand blanket needed 4 rounds of compaction. The amplitude of the equipment is also low, which means that the distance between each sand column must be reduced to 2 meters, increasing the workload and further reducing efficiency.

The ICE V230’s 38.8 tons of driving force immediately translated in significant time gains. To achieve the bearing capacity goals the client set up a protocol that lifts the vibroflot up 50cm every 20 seconds, achieving compaction rates of 150cm/ minute, completing the 9 meters within 6 minutes. The V230 easily reaches soil penetration of 9 meters, allowing the 18m sand blanket to be compacted in only two passes instead of four, a doubling of efficiency. The sand columns that the V230 built had a 3-meter diameter, and SPT values reached 41. Previously the client had achieved only 1m diameter columns, the number of columns that need to be built could be greatly reduced, and this lead to another 30% efficiency gain. The V230 is designed to work at this punishing pace; hydraulic cooling ensures optimum working temperatures on the bearings, and the circulating hydraulic oil continuously removes wear particles from the vibroflot into the power packs oil filtration system.

Because of the V230’s high speed 1800rpm set-up the crawler crane is also relieved of resonance stress.

The client was impressed by the data acquisition system: “this system gives real insight into the production process and allows us to report data for each sand column”. The depth gage gives real insight into the water level allowing the operator to adjust the position of the vibroflot for tidal changes. The working procedure for the sand columns was set as follows: pull-up 50cm when the working pressure reached 370 bar.

One of the biggest concerns in port construction is the impact of waves and water current on the equipment. At the Abidjan site environmental conditions did not affect the compaction activity. The V230 is lifted by a 150t crane operated from a large barge allowing for optimal stability and a wide operating radius. Under self-weight the vibroflot naturally achieves the required column verticality.

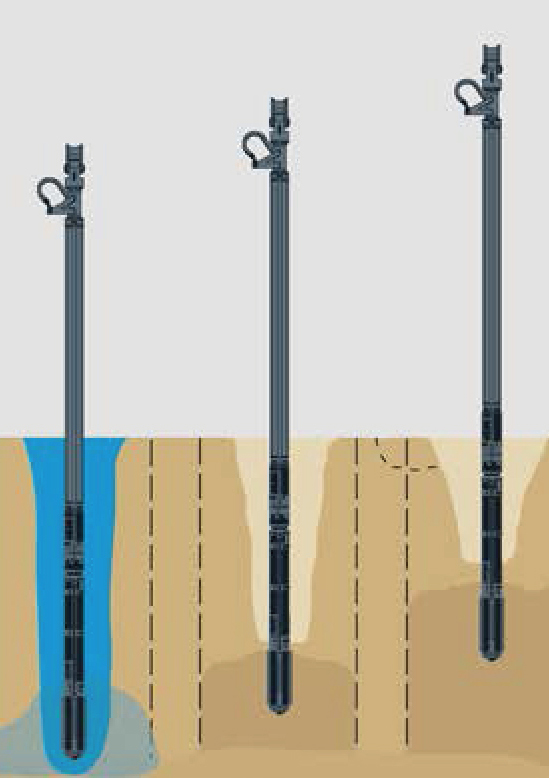

The V230 is a modular design, the length of the V230 can be extended by adding followers. CHEC ordered 6 followers to reach a total equipment length of 39m meters. The followers can be added or removed with a bolt system according to site requirements. Like most hydraulic equipment the V230 can also be used fully submerged underwater. To increase efficiency even further, CHEC decided to remove 4 followers and work with a three-follower 20m long vibroflot set-up. This reduces the weight and allows the crane to have a wider working range. A shorter vibroflot is also much easier to handle, the 40m length has to be hoisted from different points to avoid bending, while the 20m long unit can be safely hoisted from the top.

With the efficiencies achieved in Ivory Coast CHEC has built a good case for investing in quality equipment. The additional expense of investing in reliable equipment has had an immediate return on investment by the manifold operating cost savings brought by higher working efficiency.