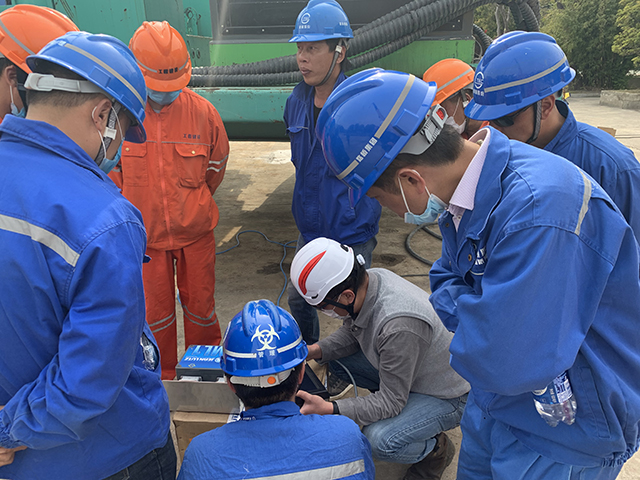

ICE service team demonstrated the verticality sensor earlier this week at test site on the STEC.

The NemoBT inclination sensor measures verticality, depths and vibration frequency. Dieseko has many years of experience with the sensor and has used it for stone column applications, as well as preparing operating protocols for vibro compaction applications where vibration frequency is a key parameter for compaction results.

The main applications for the verticality sensor are in offshore pile driving, as well as onshore applications for driving elevated casing piles highway foundations. When long piles are driven close together as they are for the elevated highway foundations, a relatively minor deviation can result in the piles running into each other at 60m depth. The sensor is also very useful for monitoring the installation of combi wall, where due to the length of the piles leaning is a risk. Incorrectly installed interlocked piles will have increasingly worsening verticality leading to installation challenges.

STEC uses a piling rig to control verticality of the pile. In this demonstration we showed the potential of using the sensor can monitor the process in real time. The sensor allows the client to make minor adjustments to the leader’s position to keep the pile within verticality tolerances.

The sensor can also be used to do frequency controlled vibro driving. We wrote about his in another article which you can read here: “Frequency-controlled pile installation increases bearing capacity”

Controlling sheet pile verticality can also be achieved by driving the piles down in a panel:

The sensor is bolted to the gear case of the vibratory hammer. The senor transmits its data through blue tooth to the touch screen DIALOG receiver unit that gives real-time data. In the photos you’ll see the Dialog sitting on a carboard box, for a more permanent installation we recommend the system to be added to the crane’s operator cabin so that the crane driver can monitor the inclination and adjust the leader during the piling work.

If verticality is a concern for your project, please get in touch with our specialists. We have a wide range of tools available to help you achieve better verticality. Such as the sensors, pile guide frames and sheet pile driving methods discussed in this article.